Repairing A Broken Piece Of Glass

Here's the video version of this article

Here is a scratch or the start of a break. It might have been caused by excess heat or a flaw in the glass. It's been circled with pen so you can see it more readily.

To replace the piece, we start by scoring the piece to be replaced many times. First one direction,

and then the other.

Then I tap from the bottom to loosen the pieces of glass. Notice that I place a garbage can below the repair to catch the debris and save myself some clean up.

I continue to tap until several pieces of glass are ready to pop out. I don't want to be too aggressive at this stage because I don't want to create pressure against the surrounding pieces of glass, or they might break.

Now I heat up a soldering iron and begin to heat the old joint, melting the solder and allowing it to drip into the garbage below. I usually flux the area needed to be melted just to encourage the solder to melt more readily. I try to direct more heat onto the side of the joint that I'm replacing to reduce the likelihood of breaking the neighboring pieces of glass.

After I melt as much of the solder away as I can, I flip the panel over and melt the other side the same way. (See the ball of solder resting on an adjoining piece of glass, that could create a hot spot and break the glass, so avoid that condition).

Now that most of the solder is removed and only copper foil is left to hold the pieces in the window, I begin to gently break and remove the pieces. I use great care not to damage the foil any more than necessary because if I don't damage the foil on the adjoining pieces, I can reuse it and save myself some work.

Once all the pieces of glass are removed, I grip the unwanted foil that encased the removed piece of glass with pliers. Pulling gently on the foil at all times, I work the soldering iron around the entire piece, allowing the old solder to melt and release the unwanted foil from the surrounding foil.

When I'm done, I have a pretty clean opening. If any of the foil is damaged, I clean the area and replace it. If this is an art glass piece you may need to create a pattern piece by placing poster board or paper under the opening and tracing it. Then cut out new glass as you normally would.

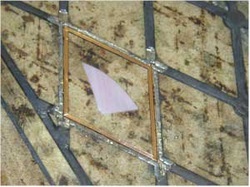

Now I set the new piece of glass in place. See the small piece of pink glass in the center, that's to keep the new piece of glass at the same height as the rest of the panel. (You can use any color of glass as a shim!)

With the glass in place, I'm ready to flux and solder.

I touch the iron to a place where the pieces line up perfectly and lightly tack them. Then I can rock the other side gently until it lines up perfectly. I do this just often enough to get the piece in place and lined up with the surrounding pieces.

Once the new piece is tacked in place, I remove the shim to keep it from creating unwanted pressure points. Now I solder the replacement piece back in place. I keep my iron at a lower heat setting and quickly span the air gap with melted solder. After I have the gap filled, I don't have to be as careful with the extra heat, because the solder won't be as easy to run through to the other side. (When the gap is so large that solder runs through, I will fill the gap with an extra piece of copper foil.)

Then I flip the window over and solder the other side.

Here, Jeanne cleans the window and dries it thoroughly, then applies a fresh coating of patina. And it looks as good as new!