Doing A MAJOR Repair

Here's a link to the video of this repair

On the way to install a stained glass panel, I did a poor job tying it down because I thought tight bungee cords might crack the glass. As we drove over some railroad tracks, Jeanne thought she saw some bits of glass fall off the trailer and we knew we were in trouble.

She inspected the damage while the panel wass still on the trailer. She did a good job, she hardly cried at all!

She inspected the damage while the panel wass still on the trailer. She did a good job, she hardly cried at all!

We laid the intact, broken panel on paper so we could trace it's outside size on the new pattern. This would allow us to put it back together and have it be the same size as it was originally.

We then moved the broken panel to another worktable and laid it on sticks which were spaced about every ten inches. This would let us drop solder and glass below the surface of the window while we worked.

I then heated the edges of the metal that needed to be removed and rocked it up and down as it cooled. By doing this, the solder joint hardened as a "cold" joint which is easy to break and often doesn't even stick.

Then I applied pressure on the metal as I moved along and soon it came away from the window.

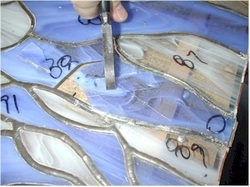

We laid out the old pattern pieces on the window. Once the broken pieces were all identified, we didn't need to lay out any more pattern pieces. We then marked the number of the pieces on the glass with a marker. And we wrote on the pattern pieces that corresponded to broken pieces with a note as to the color and direction of the glass.

I scored all the broken pieces and began to remove them with pliers, taking care not to break surrounding pieces.

Here, broken glass is beginning to pile up and holes are forming where we want them.

As pieces begin to be removed, you can see how well using the sticks worked to let melted solder run to the surface below.

I turned the panel so that the edge I was working on was close to the worktable edge. Then I could get closer to the work.

I ran a hot solder iron around the inside surface where the broken piece had been removed while gently pulling on the old copper foil. As the solder melted, the old foil pulled away and the foil on the piece that remained, stayed in place.

Next we faced the problem of how to move the fragile panel from the work table to the work surface where we had the pattern paper laid out. We realized that we could tilt the table which would allow us to pick up the piece without further damage.

Jeanne tilted the work table surface as I caught the glass and lifted it up. (See how it bent as it was lifted).

I was then able to remove solder from the backside of the panel, while it was standing vertical, so that it would lay flat.

I carried the panel to the work surface where I wanted it, but wondered how to lower it without damage. I considered letting it fall into place and hoping that air resistance would slow it enough to keep it from shattering.

We decided that a handy board would be a good support for the piece.

And we lowered it gently into place.

Then we slid the board out from under the panel like a magician pulling the table cloth from under a place setting.

Jeanne then matched up the pattern pieces to where they should go using a black and white print of the window before it was broken as a guide.

As she laid out the pattern pieces, we cut them and foiled them and laid them back into place.

Now she's all ready to be soldered again. It was a long process to get back to where we were when we started. Originally we spent two weeks building this panel and the repair took three weeks to complete. We have learned to tie panels down much more securely.

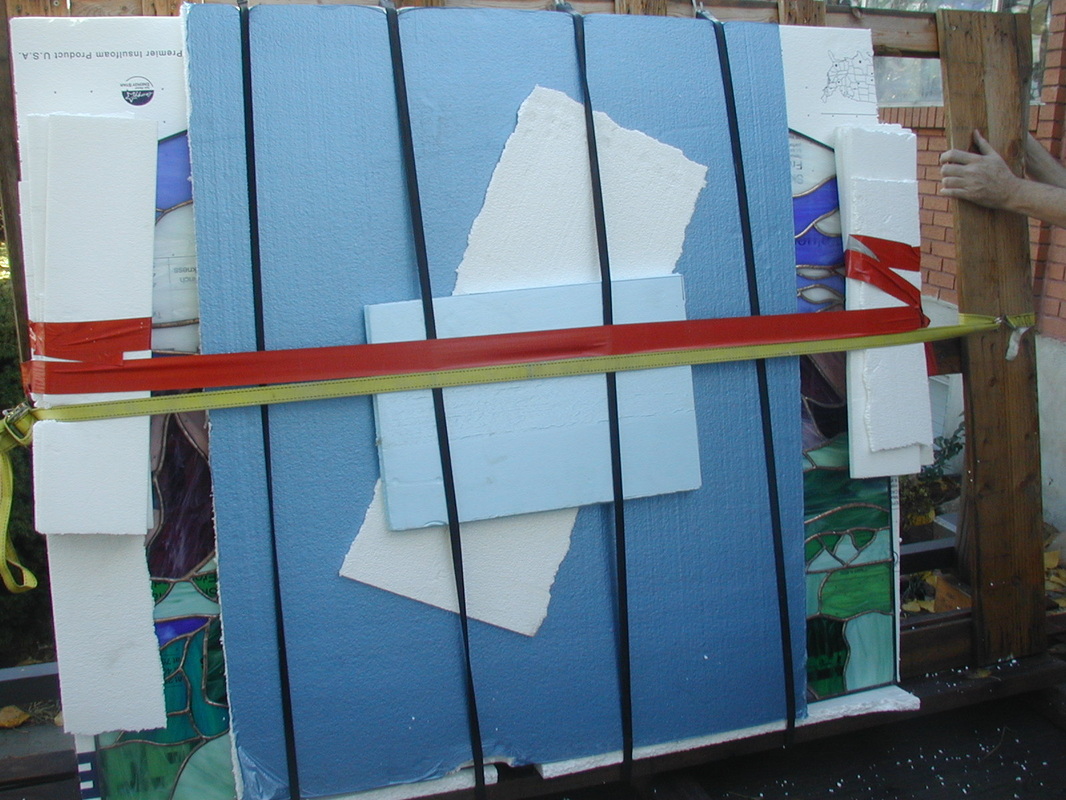

Repairing a window is much harder and time consuming than building it the first time. So shipping it with care is essential. Otherwise, you'll end up redoing work and wasting time. (This was a first time using this much foam to ship a panel and it worked so well that now we sandwich panels between entire sheets of foam insulation.)

And here she is on the day of the install, looking good as new!