How To Trim And Cut A Stained Glass Panel That's Too Long

This panel was built to fit an existing opening, but when we arrived to install the glass, some additional framing had been added, so the panel no longer fit.

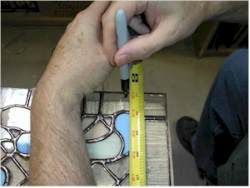

To solve the problem, I first needed to mark each end of the glass so we could cut off the same amount from each end.

When you need to trim down a window, you'll want to start by marking where it's to be cut.

To solve the problem, I first needed to mark each end of the glass so we could cut off the same amount from each end.

When you need to trim down a window, you'll want to start by marking where it's to be cut.

The next step is to draw the line to be cut using a square to keep the end true. If using outer bar, remember to cut off the extra 1/8" it will add.

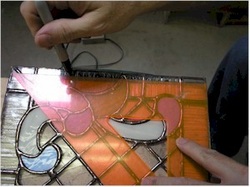

Place the panel on a flat surface so it is well supported and place a thin layer of foam or cloth under the area when the cut will be made so there is even pressure and support.

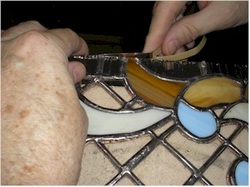

Then, score the line that was drawn earlier.

Then, score the line that was drawn earlier.

With the cut line scored, use grozing pliers to break off each of the pieces that need to be removed. (The small tip wasn't scored, it just gets broken with the breaker pliers)

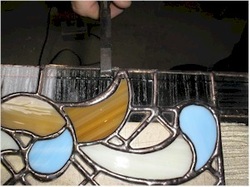

The pliers allow the glass to be broken but it's still held in place by the solder. So slide the panel just over the edge of the work bench, place a trash can under the place you'll be soldering and heat up the lead line with your soldering iron.

Allow the solder to drip into the trash can below.

Allow the solder to drip into the trash can below.

Rock your pliers down and out slightly, pulling out the piece of glass gently.

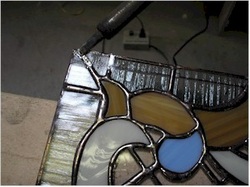

De-solder the lead lines where the glass pulled out easily. Try to remove extra solder that's sticking out so you'll have a flat spot to form the new edge of the glass panel.

You may find it helpful to hold the old copper foil as you de-solder the lead lines. A slight twist as the lead liquefies allows the foil to tear away, leaving a flat, crisp edge.

A final rub of the edge with the solder iron flattens the old lead line.

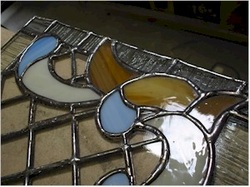

With the old glass and solder removed the edge is done except for the protective copper foil and lead covering. Wipe away the flux with a rag so new copper foil will stick.

Add some new foil to the edge.

Tin the edge just like you do on a new window.

Clean and patina the edge so it looks like the older section of glass.

Now do the same thing on the other end of the panel.

Now do the same thing on the other end of the panel.

Now that the panel is shorter, it's fits right into place.