Fix or Reinforce Glass With A Solder Bridge

This is a panel that we built which had a weakness in a long thin section. We built several of them and they would sometimes crack at the thin point of the glass. So to keep that from happening and to reinforce the weak spot, we needed to reinforce the spot where the break was taking place.

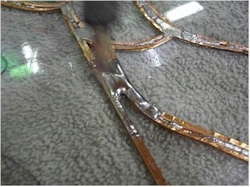

The back of this piece is already repaired, you can see the bridged solder bead on the back of the panel.

First, add solder to the foiled edges like you would in any other soldering job.

Then add a bead, usually just one drop, of solder to bridge between the two solder lines. Touch both edges of the soldering iron tip to each of the solder lines you are bridging.

As the bead is laid down, it looks very wide and fat.

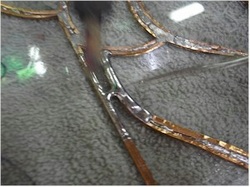

But when the solder iron is lifted up, the bead rounds up on top and the repair looks perfect.

This technique works on very thin spaces, where there is only a short gap to bridge. If you have a larger gap, you'll want to add a piece of copper foil to the gap (applying it to the surface of the glass) to give the solder a place to adhere to.