Converting To A Lead Free Studio

Click Here For The YouTube Video

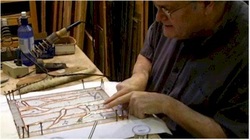

Recently Jeanne attended a health fair and they offered a blood-lead test for a small fee. She took it out of curiosity and found that she had 0.06 (6 micrograms) of lead per deciliter of blood. The old standard was 0.10 or higher in children and 0.40 in adults was considered dangerous. Recently the CDC has lowered the standard for children to be 0.05

No amount of lead is safe and 0 is normal. So we decided to get rid of it.

No amount of lead is safe and 0 is normal. So we decided to get rid of it.

When soldering using lead free, the iron must be hotter, we use the same flux and the solder doesn't flow as readily.

Here I'm using 50/50 solder and it flows easier.

With the lead free, I have to drag the solder along and baby sit it every step of the way.

The tip seems to get dirty faster than with leaded solder and so you have to work to keep it clean.

Electronic manufacturers report that tips don't last as long in their industry now that they've converted to lead free soldering.

Electronic manufacturers report that tips don't last as long in their industry now that they've converted to lead free soldering.

I use a water soaked sponge to keep the tip clean. I also use a sal ammoniac block to keep the tip "tinned" well.

I can tell that this method takes a little more work, but it will probably become easier as I get used to the new techniques.

The flow is different, it's almost like you forgot to flux.

The flow is different, it's almost like you forgot to flux.

With the lead free I have to put the solder right on the tip. It doesn't flow off easily.

The lead free costs about 50% more than solder with lead, but it is very shiney when applied. Folks who make sun catchers and jewelry will love the results.