Build Your Own Work Bench

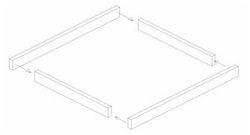

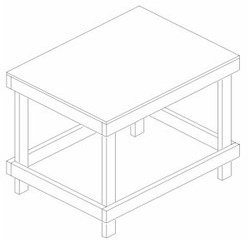

1. Start with the top frame which is made of 2 sets of two by fours, 2-48” long and 2-33” long. The total dimension of the top frame will measure 48” x 36” when screwed together. Use glue at the joints and run two 3-1/2” deck screws in the long 2 x 4’s at each end to join them to the shorter boards. (Some folks like to add additional strength to the table by adding an additional short board in the middle of the frame, but this is not necessary).

Build 2 of these frames at the same time, the second will serve as the footrest and bracing for the legs.

Build 2 of these frames at the same time, the second will serve as the footrest and bracing for the legs.

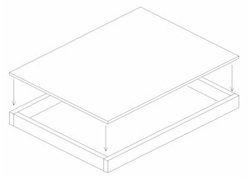

2. Next, screw the 48” x 36”, ¾” (or ½”) particle board top to the top frame (you may substitute with plywood if desired). You may want to just use screws (no glue) to attach the table top to the frame so that it will be easy to replace it if you ever need to. Screws to attach the top should be spaced 6” apart and be at least 1-1/2” in length.

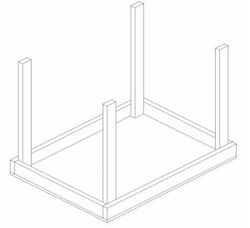

3. Next, turn the table top upside down and attach the 4 32-1/2” legs to the table top. The boards should rest inside the framework and touch the underside of the table top. 3-1/2” screws should be used to attach the legs and they should be run into the legs from both directions.

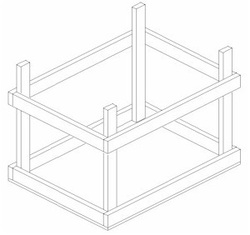

4. Before turning the table over, measure down on the legs 8” and attach the extra frame work you built in step 1. When you turn the table over, the top of the frame will be 11-1/2” from the floor, a good height to be able to use as a footrest and to be able to sweep under.

Some folks like to add a shelf to the top of the foot rest for storing light objects. This is best done when the table is turned over. Also, a ¾ thick x 1-1/2” wide cleat added to one side of the workbench will give you a good way to use a strip cutter.

Some folks like to add a shelf to the top of the foot rest for storing light objects. This is best done when the table is turned over. Also, a ¾ thick x 1-1/2” wide cleat added to one side of the workbench will give you a good way to use a strip cutter.

Bill Of Materials 6 – 2 x 4 x 8’

1 – ¾ x 3’ x 4’ particle board or plywood

3-1/2” Deck Screws

1” or longer screws for top attachment

Glue

Optional – ¾ x 1-1/2” choice lumber for cleat

Cut List

4 – Long Frame Pieces – 48”

4 – Short Frame Pieces – 33”

4 – Legs – 32-1/2”

1 – ¾ x 3’ x 4’ particle board or plywood

I hope you enjoy using your workbench.

1 – ¾ x 3’ x 4’ particle board or plywood

3-1/2” Deck Screws

1” or longer screws for top attachment

Glue

Optional – ¾ x 1-1/2” choice lumber for cleat

Cut List

4 – Long Frame Pieces – 48”

4 – Short Frame Pieces – 33”

4 – Legs – 32-1/2”

1 – ¾ x 3’ x 4’ particle board or plywood

I hope you enjoy using your workbench.

Below are photos of putting a shelf on the bottom of the table.

You need to notch out the plywood, so that the shelf will fit around the legs of the worktable. It's a good idea to install it before the top goes on.

Otherwise, you'll have to bend it to get it in place and that's not a really elegant way to do things.

But, here's the shelf, not ten minutes after installation and it's already being put to good use.

And here's a more traditional way to add a shelf. Just add a row of boards.