Building A Four Sided Lamp

The four sided lamp is made of four flat panels. This is a traditional mission style inspired by flat panels of the 19th century. (you can download the pattern by clicking here).

The sides are built using the same techniques as any flat panel. Precision is more important, because the pieces will need to be the same to fit together properly.

...Select opaque glass so that light from the bulb doesn't burn through the lamp when it's in use.

The sides are built using the same techniques as any flat panel. Precision is more important, because the pieces will need to be the same to fit together properly.

...Select opaque glass so that light from the bulb doesn't burn through the lamp when it's in use.

Once it's laid out, solder each of the four panels as you normally would and tin the edges. Use care to make the tinned edges smooth so they will fit together easily.

Once all four are soldered, you'll be able to start putting the lamp together. Start with two of the panels and tack solder them, then add another panel and the last. The shade will be very unstable and may not even be as square as you want it, but that won't be the case much longer.

Measure for the top cap that will hold the shade in place. We used a brass kick-plate for this shade, copper and brass are the most common materials for top cap and can be found at most sheet metal shops.

Tin snips make it easy to cut the square to size.

You may then need to flatten it back to a flat shape.

Since we have the sander left over from furniture building days, I smoothed out the edges, an extra step that wasn't absolutely necessary.

Then I stamped our name in the cap, since this is not only a piece off art, but could be collectible in years to come.

The finished stamping.

Then drill a center hole just the right size for the pin on the lamp to fit through.

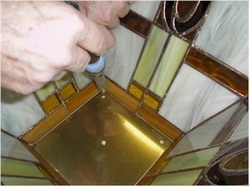

Now place the cap at the bottom of the shade and square up the panels so that there is the same amount of gap on each side. This will insure that the whole shade is square.

Solder the cap to the shade and the shade will go from weak and unstable to firm and fairly rigid.

Solder the cap to the shade and the shade will go from weak and unstable to firm and fairly rigid.

Now you can solder the outside lead lines completely. Place the lamp shade in a box filled with crumpled newspaper and shift it so that the lead line you're soldering is horizontal.

Turning the temperature down on the soldering iron may help to keep melt through at a minimum.

Turning the temperature down on the soldering iron may help to keep melt through at a minimum.

Once the outside is soldered a quick pass along the inside corners will smooth them nicely.

Then clean, patina and polish as you would any other project.

The completed lamp is done and looks marvelous.