How To Build A "Double Foam" Crate

When a window arrived at a clients address, with a slight crack in the border glass, we were very glad that we had built the crate to specifications. The insurance on the parcel was more than enough to cover the replacement of the glass, but it is a nuisance to have to build or repair the glass and the customer is inconvenienced.

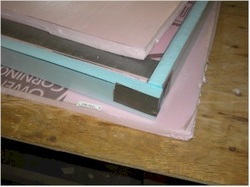

The secret is to keep the damage from happening in the first place. And that means adding extra foam to the packaging. Here is a piece of glass with 1" of foam on the top and bottom of the panel to protect it.

Edge foam is marked to protect all four of the edges of the glass.

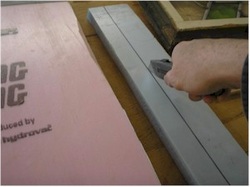

A utility knife is used to score the edge foam.

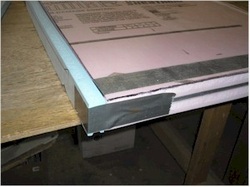

The foam is placed to surround the perimeter of the package.

Then we place the package on to another layer of foam to cut it to size to be doubly sure the panel is protected.

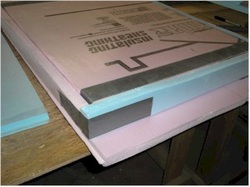

A piece is cut for the top and the bottom of the package.

Then the edges are treated with another layer of foam. With it completed, there are two 1" layers of foam protecting the glass. A total of 2" surrounding the glass on all sides.

We glue and staple sticks to the plywood we build the case from to add support to the case.

The ends are nailed to the sides of the box.

The top is screwed on so that the crate can be easily opened. We sand the wood to get rid of all sharp edges.

The finished case rests here, relaxing against a sofa, waiting for a ride to the delivery store.

We've found that we can save some time and materials by simply building the foam part of the crate, straping it together with duct tape, and taking that to the UPS store and having them put it in a larger box which gets filled with styrofoam peanut packing material. It's lighter, it cushions the glass more and their insurance stands behind it since they did the final packing.

We've found that we can save some time and materials by simply building the foam part of the crate, straping it together with duct tape, and taking that to the UPS store and having them put it in a larger box which gets filled with styrofoam peanut packing material. It's lighter, it cushions the glass more and their insurance stands behind it since they did the final packing.

***Update***

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.

We frequently use the techniques described in another article: How to build a multi-crate.