How To Solder For A Stained Glass Repair

In another article we showed how to repair this damaged panel, to see that article click here.

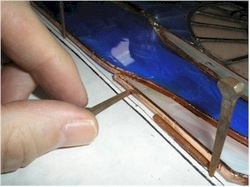

Now that our pieces are cut and foiled, we're ready to solder them into the window. But there's an obstacle, the glass doesn't sit as high up as the old glass, the solder edge on the other side is keeping the original window higher than the new pieces.

The fairly easy solution is to place little pieces of glass so that the repair pieces can rest on them. These pieces should run fairly thin so that the glass edges line up with each other.

You can see that the first blue piece now lines up with the original window. The cloud piece has been left out so you can see the small glass pieces that it will rest on.

Now you can see the cloud is lined up, there's a "glass shim" ready for the next piece of blue glass. You can also see the new piece of foil that's been placed on the bonnet to replace one that was damaged when the old pieces were removed.

When an edge of the glass isn't up quite high enough simply take a horseshoe nail and use it as a wedge to raise the glass up to the proper level by sliding it sideways under the piece until it rises to the proper level.

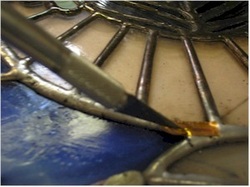

Apply flux and tack all the pieces so they won't move around.

Here, there was a bit of a gap so it gets filled by dragging the iron with some solder across the opening 90 degrees to the gap. This allows some solder to bridge the gap but doesn't get the joint hot enough for the solder to flow through to the other side of the window.

Leave some space between each bridge so that the solder has a chance to cool. This keeps the solder from getting hot enough to run all under the window.

Here, there was a bit of a gap so it gets filled by dragging the iron with some solder across the opening 90 degrees to the gap. This allows some solder to bridge the gap but doesn't get the joint hot enough for the solder to flow through to the other side of the window.

Leave some space between each bridge so that the solder has a chance to cool. This keeps the solder from getting hot enough to run all under the window.

This is more of a concern than when the window was originally soldered because when you first solder a panel, the first side has the glass sitting flat against the table and there's no place for solder to go and when you get to the second side the bottom has been sealed.

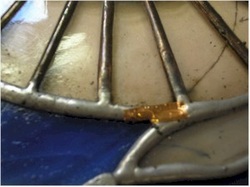

Here, the spaces between the "stitching" have been filled on the other side.

Here, the spaces between the "stitching" have been filled on the other side.

Once the gap has been bridged, you can finish the decorative soldering to make the top look nice. This is a place when turning down the temperature of the iron or cooling it frequently by rubbing it on a wet sponge keeps solder from getting too hot

Work your way up each side of the panel, connecting the lead lines to the new metal and solder the corners.

On the other side, you'll find many bulges of solder that tried to run through. By touching them and dragging them to the spots where they are needed, you may need very little extra solder on the back side of the panel.

Here, a piece of new copper foil has been placed over a spot where there was a gap. To do this successfully, take a rag and wipe the area fairly clean. If you have a lot of flux on the glass it will be difficult to get the foil to stick.

Take a craft knife and trim the foil to the profile of where the lead needs to go. You may want to hold one end down with a finger as you pull against the foil with the knife.

With the foil trimmed to the correct shape, you can add flux and solder the foil in place.

Touch the foil at one end, allow the solder to melt and once it sticks, pull off of the foil so you don't accidentally move it around.

If the foil tries to move on you, use the craft knife to hold the foil in place as you solder.

If the foil tries to move on you, use the craft knife to hold the foil in place as you solder.

You can then move to the opposite end of the foil and solder it. Let the solder below the foil melt and push the copper down using the iron tip until it is covered with solder.

It may touch down to the glass below and that's good as long as you don't heat it up so much that it begins to run through to the other side.

It may touch down to the glass below and that's good as long as you don't heat it up so much that it begins to run through to the other side.

Once the foil is covered and filled in, you may find a place that is slightly misshapen. Fix this by cleaning away the debris with a rag, reflux and touch the solder, melting it and then pull up to allow the metal to spring back into the shape gravity pulls it to.

If you still have an undesirable lump, try trimming back the line with the craft knife and re-melt.

If you still have an undesirable lump, try trimming back the line with the craft knife and re-melt.

Continue along fixing the lead lines, moving solder to where it needs to go by melting it, pulling it up with the iron and depositing it in another place.

Eventually, you'll find that the entire repair is complete and you'll wonder why it seemed like such a big deal to face a repair.

Here she is, after being cleaned, patina'd, waxed and polished. As good as new and impossible to tell that there was ever a repair done to it.