How To Ship Big Stained Glass Panels

To ship a big piece of glass, it needs to be crated. We build a crate around every big piece of glass which we ship. It needs to be a custom fit so that the glass can be adequately protected. The following pictures are of us building a crate for a 3' by 5' window. We use similar techniques when crating smaller windows.

We have the stained glass panel laid out on a different table than the one we're going to build the crate on.

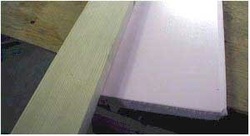

First we lay the 1" thick rigid foam insulation on the table. This comes in pink or blue depending on the brand you buy.

We lay the panel to be shipped on top of the insulation and use a box knife to cut around the panel. We cut right on the edge. We don't want any extra foam hanging beyond the window edge.

Then we slide the cut line of the foam over the edge of the table and push down to break the foam. If it has a membrane holding it together, we run a utility knife along it to cut it off. We use the cut off pieces as a template to cut the second piece of foam the same size as the first.

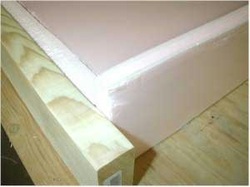

Then we take a two by four and use it as a pattern to cut four pieces of filler pieces of foam.

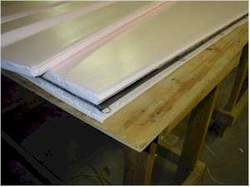

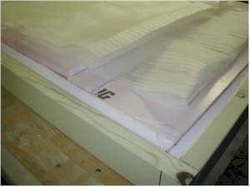

Here we have the "foam, glass, foam sandwich," with some of our cut pieces laying on top.

Next we take the long pieces and cut them to the length of the sign and set one on each side of the sign. Then we stand up a two by four along the long edge and mark a cut line a two by four width from the end of the sign.

(We make sure that the other end of the two by four is hanging out a two by four width at the other end when marking) The cut two by four is then cut a saw blade width short so the box will keep the foam tight. We cut a second one for the other side.

Here is the foam "sandwich" with another piece of scrap foam on top of the pile to raise the top of the entire package to the height of the two by four frame. You can also see the two by four side piece ready to be put in place.

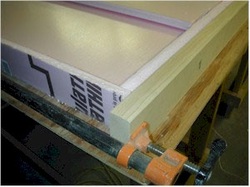

Now we use a clamp to pull the two by fours together on each end. We only apply a slight amount of pressure to the clamp. We want the crate to be tight but not so tight we damage the foam and drive it into the stained glass we're protecting.

We cut and attach our connecting two by fours. Then we check that the top of the crate is even with the two by four framework. Then we add a couple of layers of foam blanket to the top so that the lid of the crate will apply a slight amount of pressure when it's in place.

Because we have an inch of foam on the top and bottom and all around the glass inside the crate, it is safe to screw down the plywood top of the crate. We laid the plywood on top of the framework and traced around it and then cut it out.

Next we got some friends to help flip the whole assembly over.

Then we laid the final piece of plywood down and screwed it in place.

When we ship, we find that moving van lines have a good system in place to haul sensitive and delicate items, such as electronics and stained glass. They cost 3 or 4 times more than common carrier, but you get what you pay for.

***Update***

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.

There's also a video on YouTube about building a glass crate, his techniques are fairly good, make sure and build yours so you can fit 2" of foam all around your glass.