How We Crate Same Size Multiples of Glass

There is a time when we need to ship several panels and a little more weight in one crate costs a lot less than shipping several different crates.

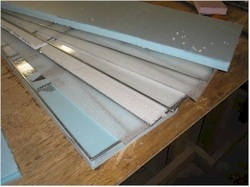

Here are three windows stacked up with 1" rigid foam on the top and bottom and thin bubble foam between each layer of glass.

As the panels are stacked up, new foam and sheeting are cut to size.

The foam and glass stack form a nice, neat stack.

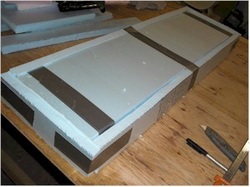

The foam stack is completed with a rigid foam outer shell which is duct taped together to keep the foam in place.

(There is 1" of foam between each panel of glass and 2-1" pieces on the top and bottom and surrounding the edges of the glass).

(There is 1" of foam between each panel of glass and 2-1" pieces on the top and bottom and surrounding the edges of the glass).

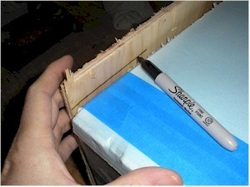

Then we place plywood up against the foam stack and mark it to cut it.

1" sticks are stapled and glued to the wood to provide something to attach other panels to.

End panels are fitted to each end of the crate.

The end panels are nailed to the 1" sticks that were stapled to the side panels.

The top and bottom panels are cut to fit the crate.

The top is screwed on so that the crate can be easily opened.

We sand the wood to get rid of all sharp edges.

We glue many extra labels to the crate.

This type of crate is very light weight and is strong enough to protect the glass

We recently shipped a panel in the foam package without plywood and in a cardboard box supplied by UPS. The two panels arrived with cracks which we'll have to repair. The moral: stronger make sure the box you ship in is over-sized and that the fill it wit foam peanuts.

We recently shipped a panel in the foam package without plywood and in a cardboard box supplied by UPS. The two panels arrived with cracks which we'll have to repair. The moral: stronger make sure the box you ship in is over-sized and that the fill it wit foam peanuts.

***Update***

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.

Nowadays, we use the white Styrofoam sheets of insulation that can be obtained from home improvement centers. It has more "give" to it. Also, once the package of glass and insulation is completed, we add an additional layer of insulation all around the package. This insures that we have at least 2" of foam around the glass (which the shipping companies require).

See instructions for extra foam crate.